The blow molding process begins with melting down the plastic and forming it into a parison or in the case of injection and injection stretch blow moulding (ISB) a preform. In general, there are three main types of blow molding, extrusion blow molding, injection blow molding, and injection stretch blow molding. It is also used for forming glass bottles. We are Leading Manufacturer of PET Blow Moulding Machine in India.įully Automatic Pet Blow Moulding Machine is a manufacturing process by which hollow plastic parts are formed. In our efforts to sustain quality the team of efficient quality controllers conduct regular tests on all manufactured products and their base materials.

#PET MOULDING PROFESSIONAL#

Our professional are well versed with the latest design and manufacturing technology to ensure the production of high quality products that can be trusted for optimum performance. All professionals are selected from the finest talent in the industry and are trained in the use of technology and machinery prevalent in the company. Precision engineered these products are conceptualized and developed by expert professionals. We trust our resources for quality materials owing to the years of strong and stable ties established with them. All materials are procured from reliable and trusted resources. Only the finest materials are utilized by us in the fabrication of these products.

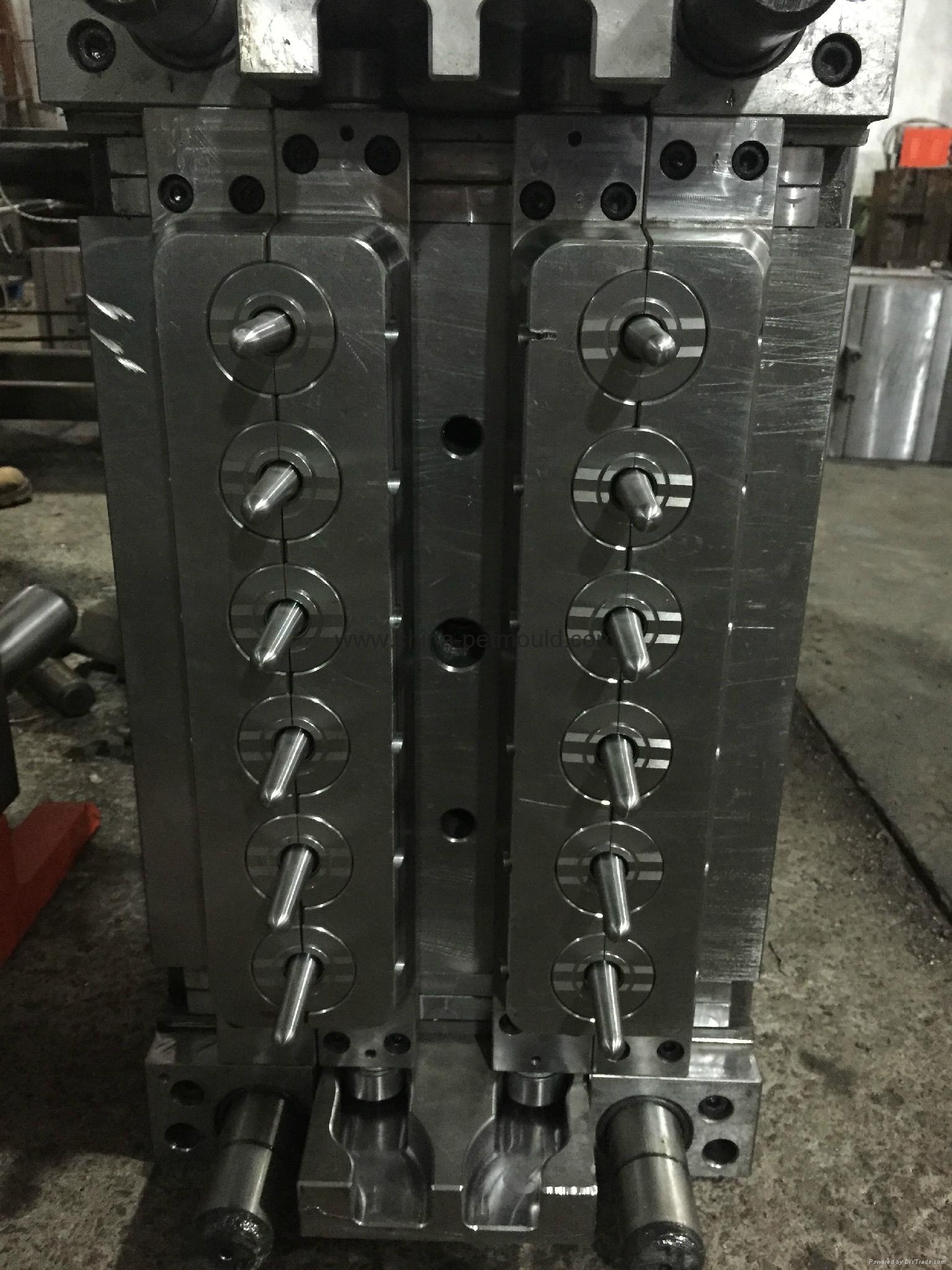

We will make different type and quantity of water manifold according to customer requirement.We offer a wide gamut of products including the finest quality, high performance Automatic Blow Moulding Machine. Special 24:1 PET screw and barrel design ensures the high quality plasticizing performance, which highly improves product efficiency and avoids traditional PET molding defects, such as bubble, crazing, discoloration, etc.ĭouble layer barrel cover that perfectly protect operator and heater bandsĮnlarged ejector force and ejector stroke satisfy the production demands for performĮquipped with multiple sets of large water manifold, improves the mold cooling, which ensures crystallization of products. Using upgraded servo system, low operation noise, strong power, fast response, guarantees low energy consumption, reduces production cost. High efficiency servo energy saving system This kind design is good for reducing material accumulation, durable and easy-to-clean. L/D ratio of 24:1 screw design, effectively control injection stroke comparing with the same level traditional PET preform machine, also improves the injection volume. The excellent plasticizing of GM2-PET guarantees the cycle time of the preform products.

#PET MOULDING SERIES#

GM2-PET series is suitable for producing preforms applied in bottles, beverage industry, food packaging industry and cosmetic industry, etc.

0 kommentar(er)

0 kommentar(er)